“Silver and gold” — when you hear these words what comes to mind? You might think of coins, jewelry or Olympic medals. What you might not think about, however, is the role these two elements play in the world of switches and the resulting thought process behind choosing silver vs gold contacts.

For a switch to connect to its application, it needs metal contacts that let the electrical current flow from one device to the other. As you search for the best switch for your needs, you might find that you have to choose between silver and gold contacts.

Let’s look at the pros and cons of these two options.

Silver vs Gold Contacts on a Switch

Silver Contacts

Silver is the most common type of contact material for switches. There are a few reasons why. First off, silver contacts are less expensive than gold. Second, silver contacts can operate with a greater range of voltages and currents compared to gold. Third, silver contacts have a very low contact resistance.

A disadvantage to using silver contacts, however, is that they can be easily tarnished by moisture and airborne contaminants.

Gold Contacts

If you’re looking for a switch for low level or dry circuit applications, gold contact materials might be the right option for you. Gold contacts main advantage over silver is that they tarnish less easily. As mentioned earlier, gold is the more expensive of the two metals. In addition, since gold is soft and pliable, it’s important to be aware of its physical limitations.

Common Question: I’ve heard that only silver to silver contacts, or gold to gold contacts, should be used for silver and gold contacts, and that gold to silver contacts don’t work. Is this true?

Answer: The contacts being discussed are internal to the switch, so the end user doesn’t have the ability to mix the two types. In general, it is best to use the same metals together instead of mixing them.

What are Contact Points?

Internal contact points for electromechanical switches operate in three different ways:

- Pushing the contact points to meet

- Wiping the contact points to engage

- Butting the contact points together

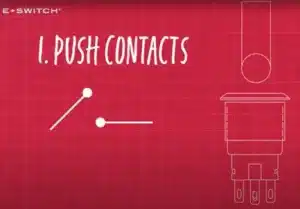

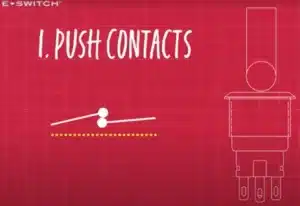

Push Contact

A push contact functions by pressing the actuator which pushes the moving contact onto the stationary contact to close the circuit. There is little to no wiping or rubbing movement, resulting in less wear and tear to the contacts. However, oxidized material can build up over time.

Switch types such as push buttons, tacts, toggles and triggers all use push contact functionality.

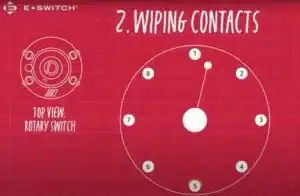

Wiping Contacts

Wiping contact functionality is common in DIP and rotary switches. The operation of a wiping contact is where the movable part of the connection wipes or rubs over the stationary part to make contact. This action can help remove oxidized material that can build up on the contacts. This is also referred to as a self-cleaning contact.

Butting/Shorting Bar Contacts

Two contact points are connected via the shorting bar. When the actuator is pressed, the contact points butt up against the stationary contacts. The rapid rate of make and break means that these switches are appropriate for high current loads.

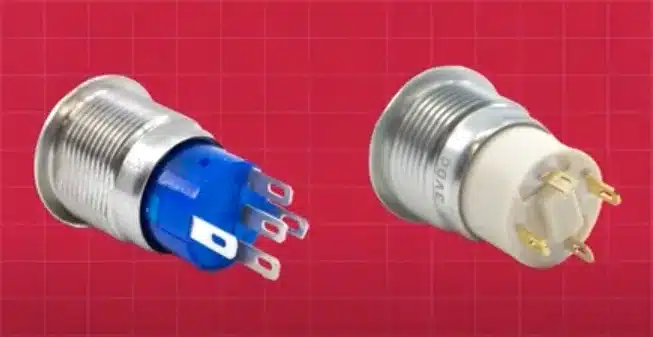

Anti-vandal and tact switches are just some of the switches that often utilize the shorting bar style of engagement.