Here are some of our most frequently asked questions. If you have a question that is not on here, please contact us.

How do I know if a switch is washable or sealed?

On the product detail page of every series you will find information about the switch. If it is washable or sealed to a certain IP rating, it will list it on the product detail page. To get to the product detail page, go to our product catalog and search by type or by feature.

How do I know if a cap is available for a switch?

If a specific product uses caps, the cap options are listed on the product detail page on a tab toward the bottom. Visit the cap options page to view all of the caps available for our switches.

How do I know if a part number is RoHS certified?

It is a safe assumption to note that all our switches comply with RoHS standards, but each product page features a “certifications” section if the switch features a certification. Simply click the certification logo to view the certificate.

Are your switches UL certified? CUL? VDE? Can you send me a file number?

E-Switch has a variety of certifications. All our certifications can be found on the individual product detail page, with a link to the file numbers.

What is your recommended solder profile?

We have solder profile recommendations for hand soldering, SMT re-flow and wave soldering processes. Visit our soldering profiles page for more information.

Do you have a cross for competitor’s part number?

E-Switch crosses our switches to many competitors out there in the industry. Simply chat directly with one of our sales representatives or contact us with the details.

What are the different seal ratings and what do they mean?

Water-Wash, Process-Sealed, IP67 Switch Seal Rating

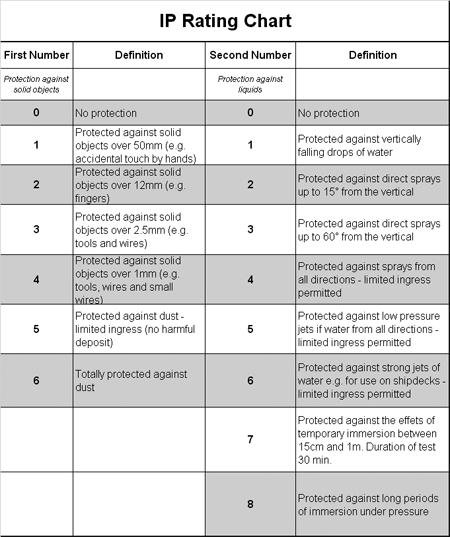

Definition of IP Codes (Ingress Protection):

IEC (International Electrotechnical Commission) 60529 Standards document specifies an international Classification system for the sealing effectiveness of enclosures of electrical equipment against the “Intrusion into the equipment of foreign bodies and mositure”.

1. Degrees of Protection – First Digit

6 Dust-tight

2. Degrees of Protection – Second Digit

7 Protection against effects of immersion from 15cm to 1m (6″ to 40″).

Based on the above, our standard for defining a “process-sealed” switch is “sealed to meet the minimum requirements of IP-67”. This means that a switch rated to IP-67 is “Dust-tight” and will pass a water submersion test at 40″ (1m), for up to 30 minutes.

Due to the variables encountered in actual water-wash machine processing, IP67 does not necessarily insure that water entry into the switch cannot occur. the water-wash pressures and air-knife drying that occurs in modern pcb machine-washing can exceed the seal requirements of the IP-67 rating.

Why can’t I run switches with the caps on through my automated solder process?

The vast majority of caps and buttons are molded using ABS (acrylonitrile butadiene styrene). This plastic is chosen because of its excellent mold and surface finish qualities, and since the cap or button is a “first surface” which is seen by the user, quality of finish is very important. Also the ability to accept a wide range of color pigments, along with good general mechanical properties, including the molding of “snap-on features” typically required, makes ABS the preferred material for caps and buttons.

However, ABS has low softening and melting temperatures, typically around 100C and 120C respectively. Continuous service temperature of 70C is typically the maximum that ABS can withstand. What this means is that ABS is NOT suitable for automated solder processing, either wave or SMT. The typical preheat temperatures for wave solder are about 150C to 160C, and higher top-side board temperatures are seen when passing over the solder wave. This will distort or melt the caps, and therefore it is recommended to install the caps after any wave solder processing. SMT is even hotter, so ABS can never be considered for SMT.

Some ABS variants may withstand the wave solder process, but this will have to be evaluated on an individual basis by the customer using their specific equipment and processing parameters. Flame retardant additives can increase the softening and melting temps, but again these require evaluation by the customer with their specific processing equipment.

In summary, ABS is used for caps because it has excellent molding and cosmetic properties, but it is typically not suitable for automated manufacturing processing that exceeds 100C, or for end-use applications that exceed 70C.